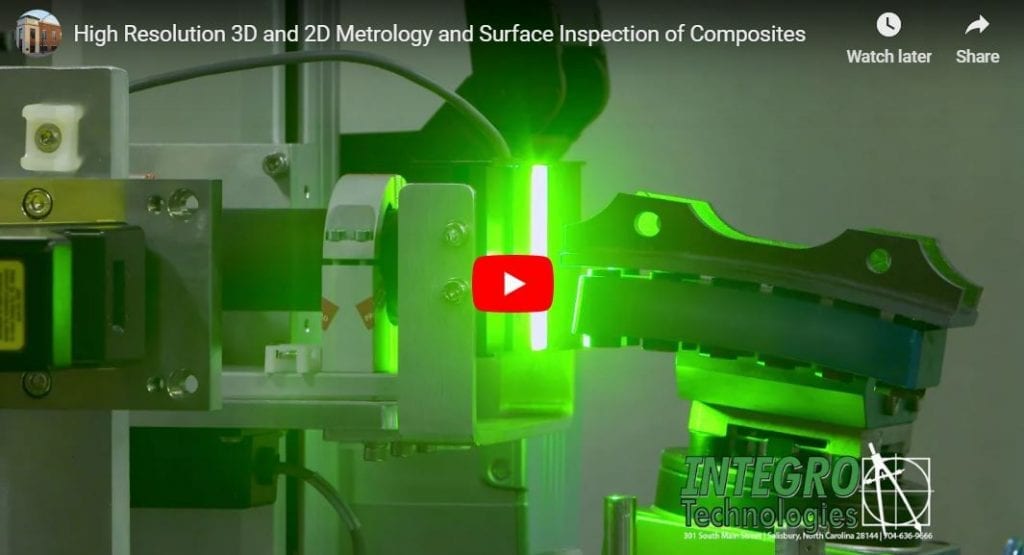

High-Resolution 3D and 2D Metrology and Surface Inspection of Composites

This vision inspection system from Integro Technologies enables automated, ultra high resolution linescan imaging and inspection of composite aircraft engine parts. The inspection occurs in 2 stages. First, the 3D sensor generates a 3D point cloud of the face of the composite part and calculates the relative angle of the plane fitted on the face with respect to the position of the 3D sensor. Second, feedback from the 3D sensor is used to precisely orient the part face to the high resolution linescan imaging system, and the part is imaged. The part is imaged with the linescan camera at two positions along the vertical axis, and then the high resolution images are “stitched”. The final stitched image is then automatically inspected to generate a report on its dimensional analysis. This process can easily be modified to enable automatic part load/unload using robots.

Please contact us today to investigate a potential solution to your 2D and 3D inspection needs.