Machine Vision offers cost-saving defect detection and innovation upgrades

“Machine vision helps manufacturers and suppliers prevent defects throughout the production process.” Integrating machine vision automation is now highly successful in inspection, gauging, and robot guidance, and it is “increasingly cost-effective and simpler to implement.”

Lenses are the superior eyes of Machine Vision

Today’s machine vision inspection systems can offer inspection of base functions: measurement, counting, decoding, and location. Lenses are a component in machine vision systems, and choosing the right optics is part of the process of developing a machine vision system, along with camera selection and the tools for inspection.

According to AIA, “Ideal lenses produce images that perfectly match the object captured, including all details and brightness variations. Standard lenses may be about a megapixel in fixed focal lengths of 4.5-100mm. Macro lenses are optimized for close-up focus. Telecentric lenses are used in specialized metrology applications. They are used to eliminate dimensional and geometric variations.”

Machine Vision lenses identify defects better than the human eye

From pre-production to the final product, machine vision lenses have the capability of detecting and sorting defects faster than the human eye.

- Identifying and sorting out all types of unwanted parts and imperfections from foods during the processing for human consumption. Hyperspectral Imaging (HSI) offers relief in labor-intensive industrial sorting applications to improve quality control.

- Eliminate and avoid wasted time in counting and errors, picking and placements, material waste, assembly line errors, and more. Vision-guided robot (VGR) machine vision employing 3D technology operates “complicated tasks while offering functionality variation and flexibility,” with “the ability to perform simultaneous operations in one process.”

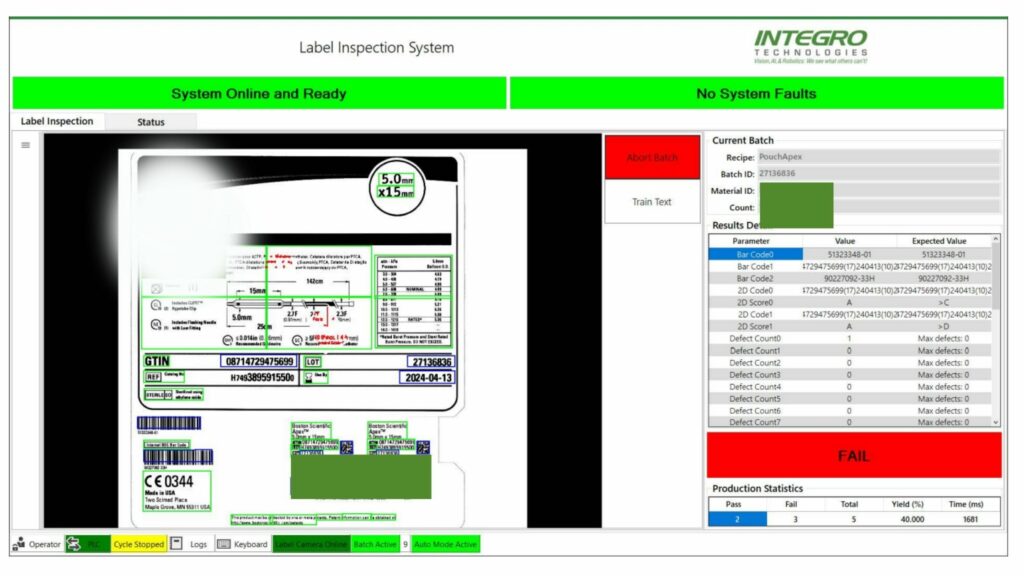

- Catch bottle, container, labeling, and other defects that can result in massive recalls. High-speed inspection systems mitigate costly production defects.

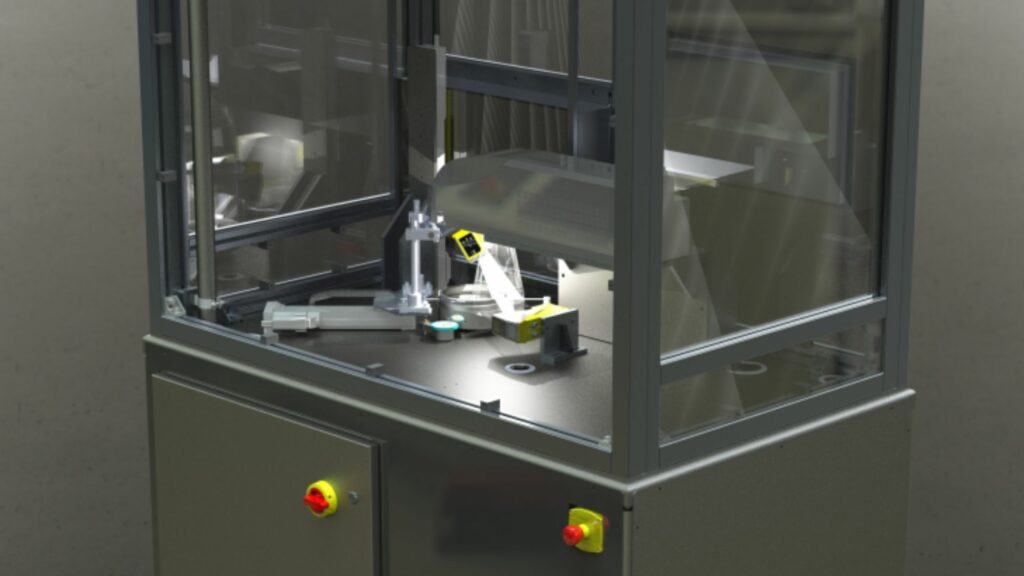

At Integro Technologies, we have machine vision solutions to customize to your industrial application. Or, we will design and develop a unique system with the right camera(s), lenses and lighting, and tools for inspection. We’re here to help you increase your production speed and accuracy, while decreasing waste in time, resources, and defective products.