Machine vision inspection technology is now being used in the electronics, solar, and conductors manufacturing process.

Machine vision inspections can deliver image resolutions and processing performance data required for high-speed component and assembly verification in a wide range of industries. These machine vision applications are highly demanding and require inspection at multiple stages in the manufacturing process, from part selection to final verification.

Integro Technologies develops solutions for manufacturers to ensure the highest quality product.

View machine vision inspection systems from Integro here or on YouTube.

This high speed, bushing inspection system inspects 300ppm. This backlit, singulation, material handling, rejection tracking

Read more

The material handling system represents a low volume 360-degree visualization and inspection solution for consumer

Read more

This 3D height measurement system by Integro Technologies is capable of imaging a variety of

Read more

This plastic container vision inspection machine was developed to inspect 100% of the internal and

Read more

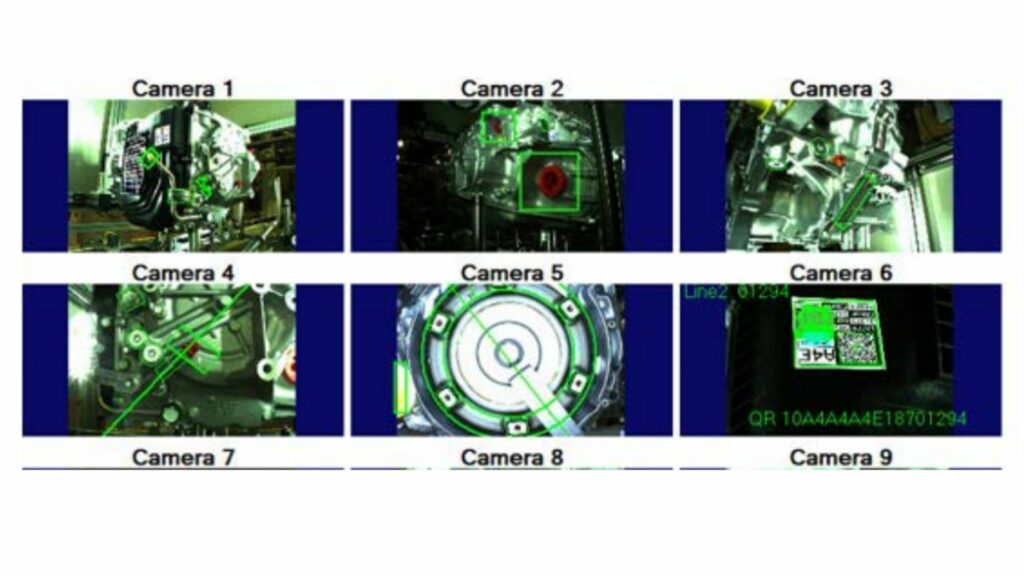

The final assembly transmission inspection station verifies the presence or absence of 47 discrete components/objects

Read more

This application by Integro Technologies is a 360° inspection of ice cream containers. Data matrix

Read more

Integro Technologies is a trusted source in machine vision technology for the food and beverage industries.

Read more

Cylindrical Bushing Internal Coating Verification and Dimensional Analysis System This high speed, (300ppm) backlit, singulation,

Read more