Thermal Pouch Sealing for Critical Packages Require Efficient Inspection

While some industry packaging applications do not require seal inspection, there are applications in the food, medical, and pharmaceutical industries that must have seal integrity without partially or weakened sealing. Not to mention a tiny opening that allows air to transfer in or out. It’s vital that critical packaging ensures inside quality. With a thermal seal inspection system, you can better inspect for compromised packages.

- Food Industry: Factors to consider affecting seal integrity in heat-sealed foods.

- Medical Industry: Recall on thousands of packages due to defect compromising sterility.

- Pharmaceutical Industry: Plastic packaging demand is leading the market.

FLIR Thermal Seal Inspection and Location are Key to Quality Seal Confirmation

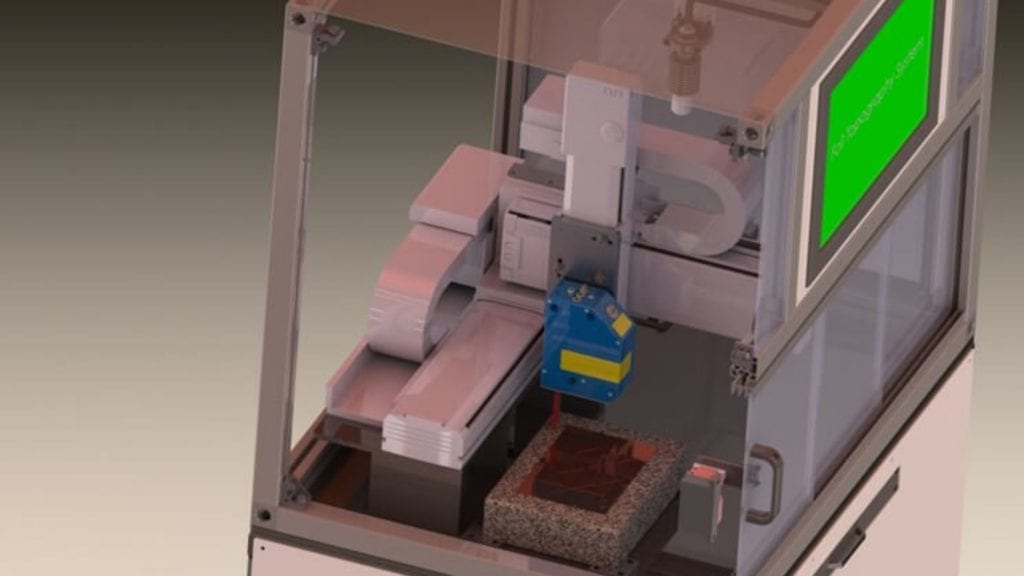

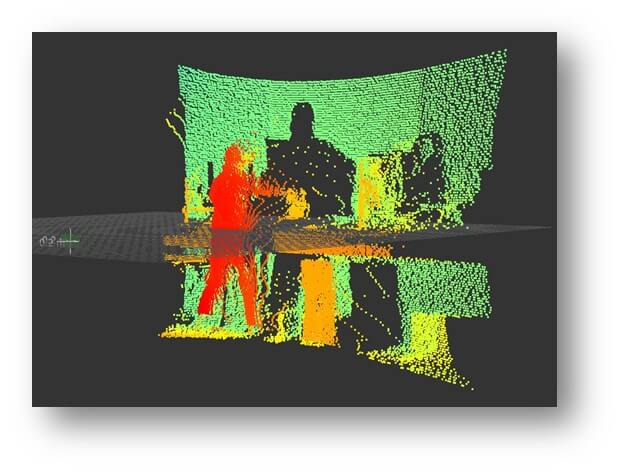

With the integration of sensor and thermal camera technology, a thermal seal inspection system advances seal defect identification. One of our partners at Integro Technologies, FLIR, allows us to integrate thermal seal inspection technology to our customers in different industries with critical packaging requirements. FLIR has an inventory of fixed thermal camera solutions.

As the sensor detects the package, the thermal camera begins scanning for seal security. Finding the best location may require multiple position tests of the equipment to achieve the best visual inspection results.

Critical packaging seal defects can add up to unwanted losses in refunds and returns. Along with other thermal imaging solutions, our team at Integro Technologies is highly equipped to help your business integrate special imaging solutions with a thermal seal, machine vision inspection systems.

As your industry leader in machine vision across many industries, we have the expertise and the partners you need to mitigate package seal defects. Contact us for the innovation that is available for critical packaging inspection.