Deep learning is becoming a commonly heard word in business, science and programming circles. However, the concept is still quite new to many people. This important type of algorithm is a subset of machine learning. It uses neural networks and pattern recognition to develop deep insights that would ordinarily be indecipherable by other types of programs. Due to increased computing power and strides in deep learning programming, this technology is driving a true technical revolution.

The easiest example of deep learning to understand is visual search algorithms. Imagine a photo of a tree. Now think of the millions of potential photos of trees and thousands of different types of trees. How is the computer supposed to know that they should all be labeled “tree” and be indexed that way in visual search? The answer is deep learning algorithms which input a “training set” of data. The program becomes generally familiar with what a tree looks like. When a new photo of a tree is inserted, it can accurately describe and categorize the image.

While advanced deep learning programs are still in the works, there are many exciting possibilities. For example, many researchers believe deep learning technology could produce ground breaking medical drugs that would cure disease and make humans much healthier. Today, scientists move to slowly with trials and experimentation to try the full range of options. However, a deep learning program may be able to create a realistic simulation that produces amazing results.

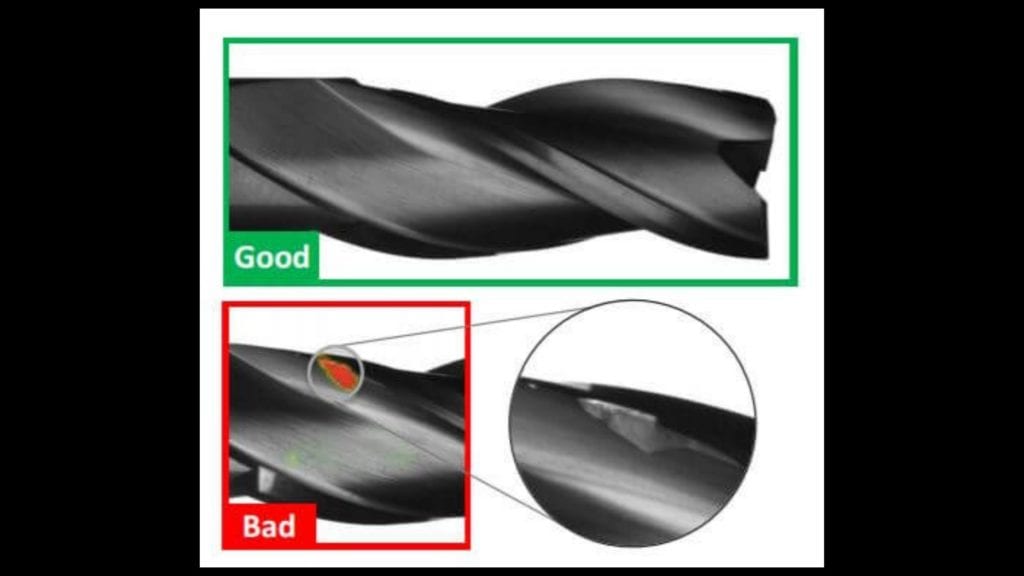

Other opportunities for breakthroughs based on deep learning include weather forecasting, quality control in manufacturing (getting mistakes below one in a million), economic models and improving machine vision systems.

No matter what, the steady advance of this technology is already having profound impacts on society and technology.

Integro Technologies is a leading machine vision integrator. For more information, please contact us today!

![]()

Machine vision learning is a relatively new disruptive automation technology that's changing the manufacturing landscape.

Read more

Over the years, the manufacturing industry has been facing mounting pressure on so many fronts.

Read more

We all know how crucial machine vision inspections are to every type of manufacturing business

Read more

Integro Technologies is proud partners with industry leaders in Deep Learning Platforms. Here are just

Read more

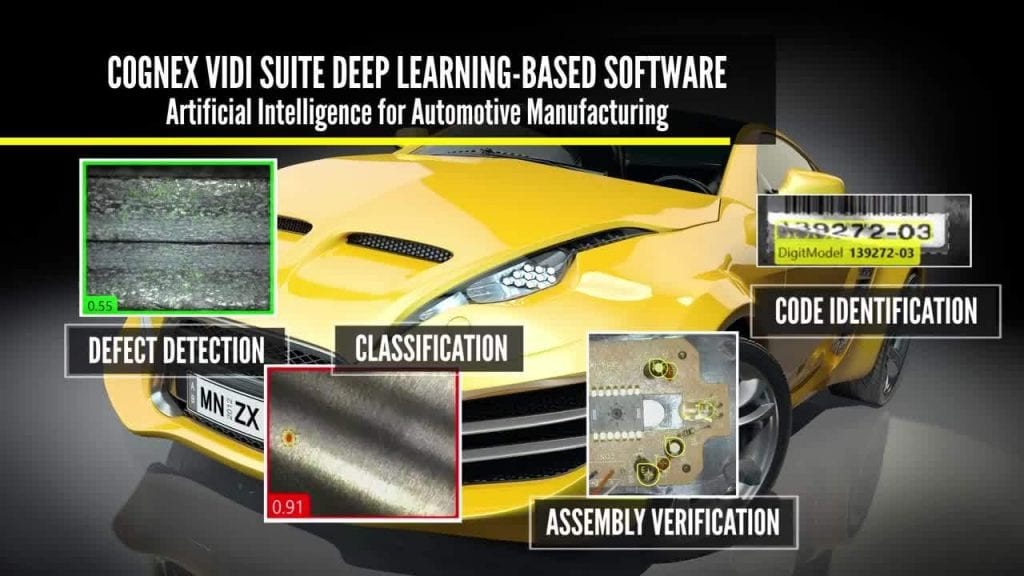

Deep learning is currently being used in the automotive industry for a number of inspection

Read more

Integro Technologies has extensive experience in the application of deep learning for classification. For this

Read more

Integro Technologies is actively adapting traditional and newer Deep Learning & AI vision related technologies

Read more

With the turn of a new century, advanced artificial intelligence (AI) and 5G technologies are

Read more

Machine Vision And Deep Learning: Change The Way You Provide Quality Products Your customers expect

Read more

What Is Deep Learning? Deep learning is a subset of machine learning, which is itself

Read more

Vision inspection is likely a big part of your operations. Whether you're in the electronics,

Read more

Deep learning solutions help manufacturers push the limits of what’s possible with machine vision. Deep

Read more

Machine Vision and Deep Learning A Machine Vision Revolution. Machine vision has become widely accepted

Read more

Technology is the road to future success for manufacturers. With new technologies like machine vision

Read more

Combining Robotics and Deep Learning Machine Vision Advances Factory Automation We know that robotics are

Read more

AI's higher intelligence is like having Superman join your quality inspection team. Imagine having the

Read more

Artificial intelligence (or AI) has seen a recent surge in use across a wide variety

Read more

Artificial intelligence, or AI, has seen a recent surge in use across a wide variety

Read more

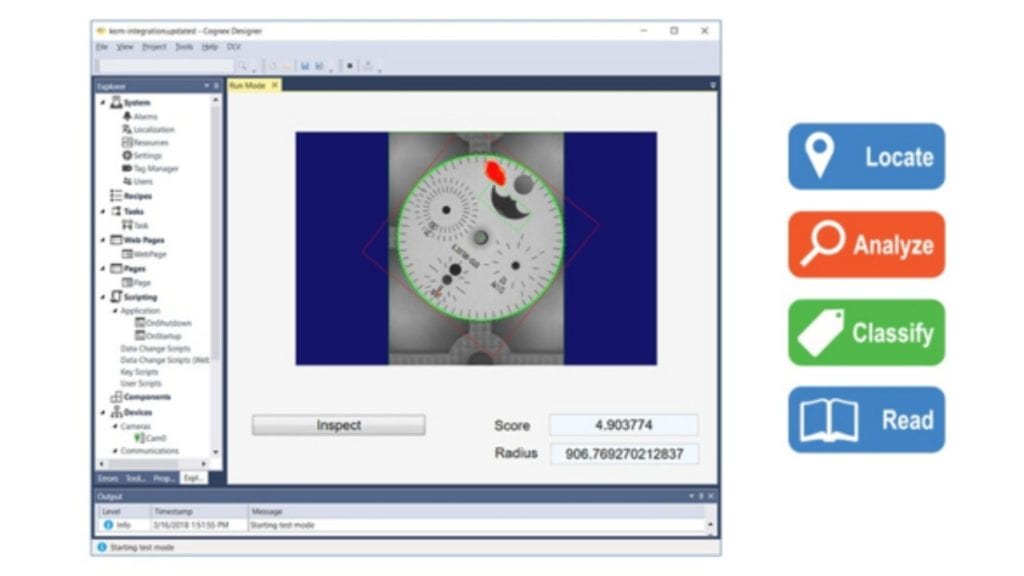

Cognex ViDi offers the first ready-to-use Deep Learning-based software dedicated to industrial image analysis. Cognex

Read more

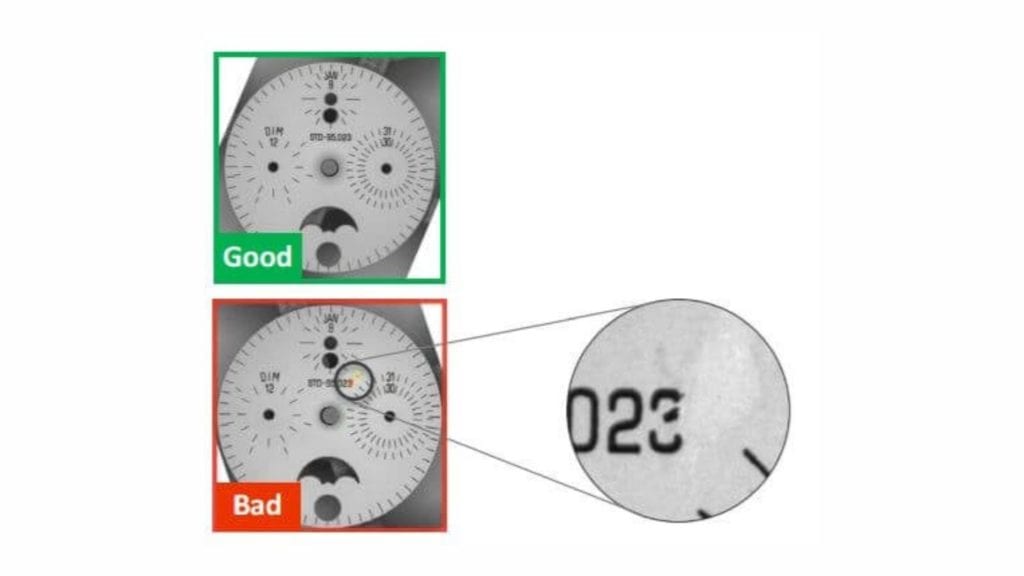

With Cognex ViDi Suite, the automated aesthetic inspection of complex pad printing is now extremely

Read more

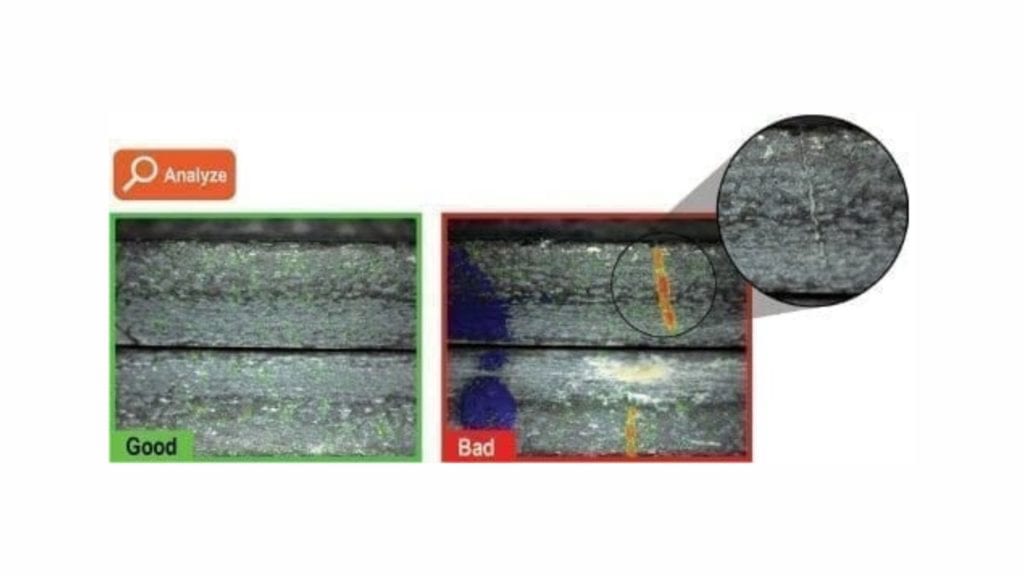

With ViDi Suite, the automated optical inspection of welding seams is now extremely simple. The

Read more

With ViDi Suite, the automated visual inspection of complex machined parts is now extremely simple.

Read more

Cognex ViDi Suite offers significant advantages in terms of performance and simplicity for configuring and

Read more

Update: ViDi is now owned and operated by Cognex Corporation Integro Technologies, a premier machine

Read more

With the ViDi red tool in its supervised mode and the ViDi green, the automated

Read more