Quality-control processes are no longer a cumbersome offline task at the end of the line. Properly integrated vision inspection systems keep production flowing seamlessly with high-speed digital precision. Quickly identifying flawed parts throughout the production line results in greater throughput and a better finished product.

When it comes to profitable manufacturing, quality, efficiency and productivity is critical — and that’s true for every function in the factory. Innovative automated vision inspection technology is helping factories improve in these areas in nearly every industry.

Quality — There are two areas that define the need for quality in manufactured products:

Ensuring product integrity for safety requirements — For some products there is an inherent requirement to satisfy higher quality control because the product may cause bodily or structural harm if safety requirements are not met. If a faulty component slips into the public and causes harm, the backlash — both in legal jeopardy and public relations damage — can sink a company. Automated vision inspection can be done at a faster rate with greater accuracy than human inspection. This enables more pieces to be inspected, resulting in a better overall quality.

Quality is a sales differentiator — A better product is always highly desirable, but it can be very costly to ensure consistently higher-grade products. Automated vision inspection makes this more cost-effective. Whether it’s a retail widget, or a wholesale component of another manufactured product, product selection is typically defined by price, quality and service. Quality is the foundation for both other factors. A superior product will have less service issues and demand a better price.

Efficiency — High-speed vision inspection is faster and more accurate than human inspection. Faster AND better? Efficiency can’t be summed up any better than that. In manufacturing, profits are driven by efficiency. As manufacturers are pressured to cut costs and improve productivity, process efficiency is crucial — and no part of the manufacturing process is exempt from that. Replacing manual inspection with automated vision inspection also reduces non-value-add touches and that makes the final product even more profitable.

Automated vision inspection not only improves the efficiency of the inspection tasks, it improves the total efficiency of the entire production line. Since more pieces can be inspected per hour, it results in a higher throughput of finished goods.

Productivity — More pieces per hour, more pieces per hour, more pieces per hour… this is the mantra of every successful manufacturing business. Innovative producers are gleaning precious gains in every area of the factory, but the improvements must be cost-effective without sacrificing quality. High-speed vision inspection is ideal for the productivity-focused manufacturer. Automated inspection systems increase daily piece rate, frees labor to do other productive tasks, and reduces product rejects and returns.

QUALITY, EFFICIENCY and PRODUCTIVITY are all interconnected within a successful manufacturing operation and high-speed vision inspection is central to improvements in each of these areas. Integration of high-speed vision inspection technology not only improves the quality-control facet of a production line, it improves the profitability of the entire manufacturing process.

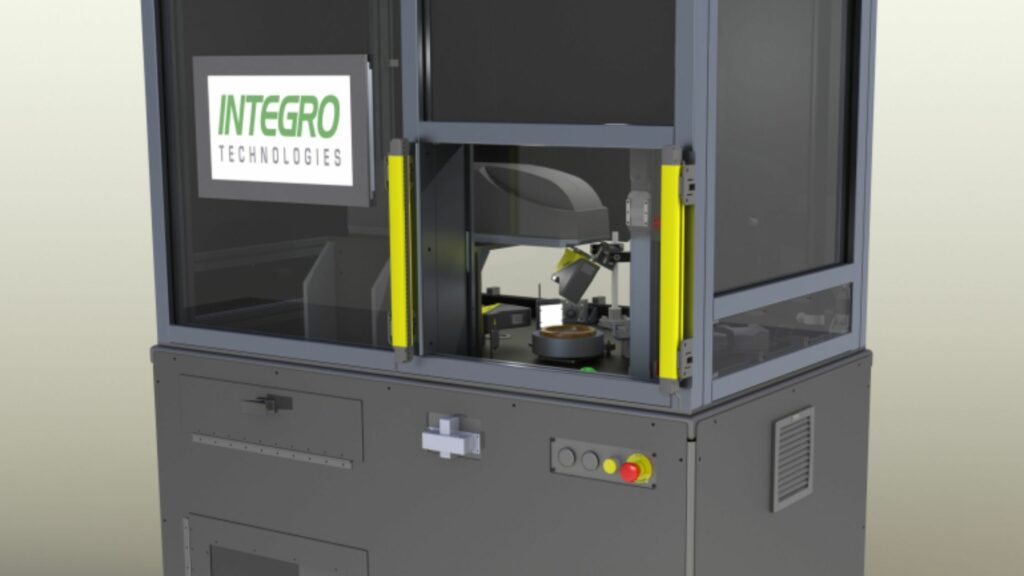

Contact Integro Technologies to help you improve your entire manufacturing process with high speed vision inspection systems.

View machine vision inspection systems from Integro here or on YouTube.

![]()

This Automotive Engine Head 3D Inspection system utilizes two Cognex DS (displacement sensor camera) 3D

Read more

Bullseye Rapid Tube and Lumen Vision Inspection System is designed to measure the outer diameter

Read more

This Automated Cylinder Drop Test automates a formerly manual drop test using a vision-guided 6-axis

Read more

The Tube Vision Inspection System (The Anaconda) is designed to inspect continuous material (e.g. surgical

Read more

The purpose of this inhaler count verification application is to verify the digits on the

Read more

The purpose of this Medical Bag Inspection System application is to inspect medical bags in

Read more

The purpose of this manual linescan station application is to identify damaged product during or

Read more

This metal web inspection application inspects six-inch webs of aluminum bonded to steel. A strip

Read more

The large paper roll inspection system is designed to locate paper labels attached to the

Read more

The final assembly transmission inspection station verifies the presence or absence of 47 discrete components/objects

Read more

This vision system inspects rivets, springs, flange tabs, and other parts on a torque converter

Read more

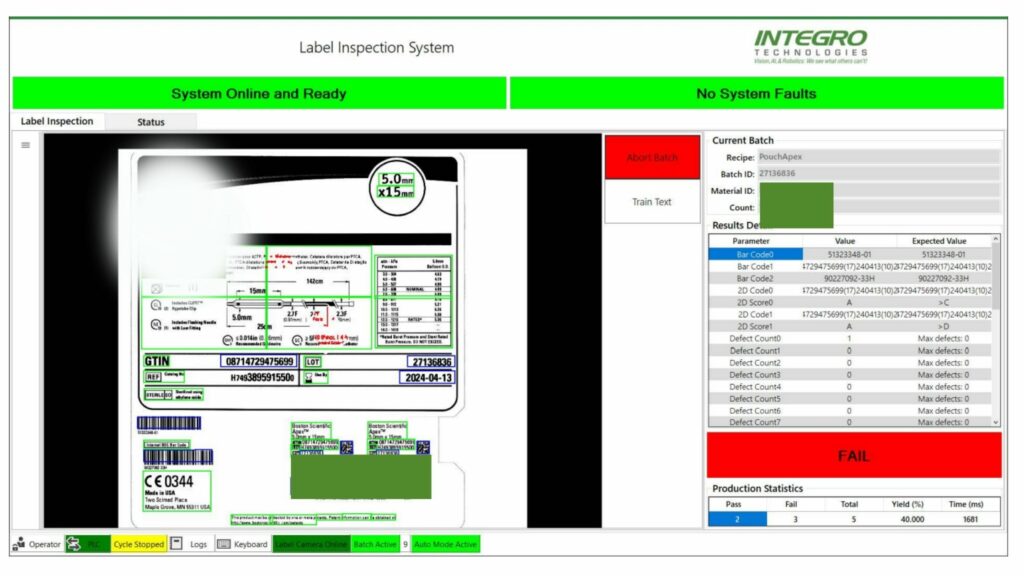

The inkjet label inspection system enables the end-user to print text or a label on

Read more

This deep learning label inspection application is an automated machine vision system for printed labels

Read more

This web registration inspection system inspects a number of different web width and print characteristics,

Read more

The thermal seal foil inspection system is capable of inspecting seals of varying diameters, and

Read more

The function and purpose of this EBC Pump Filter Inspection application is to detect multiple

Read more

This system inspects tubes for the automotive and aerospace industries. The parts vary in size

Read more

This round disk part inspection is an ideal vision system for 360 degree part inspection.

Read more

This application inspects presence or absence of decal and logo inspection on snow blowers for

Read more

Automated 3D Automotive Weld Inspection system inspects electrical contacts prior to a laser welding operation

Read more

Integro offers this as a customized, turnkey, Automated Bead Inspection solution to inspect 100% of

Read more

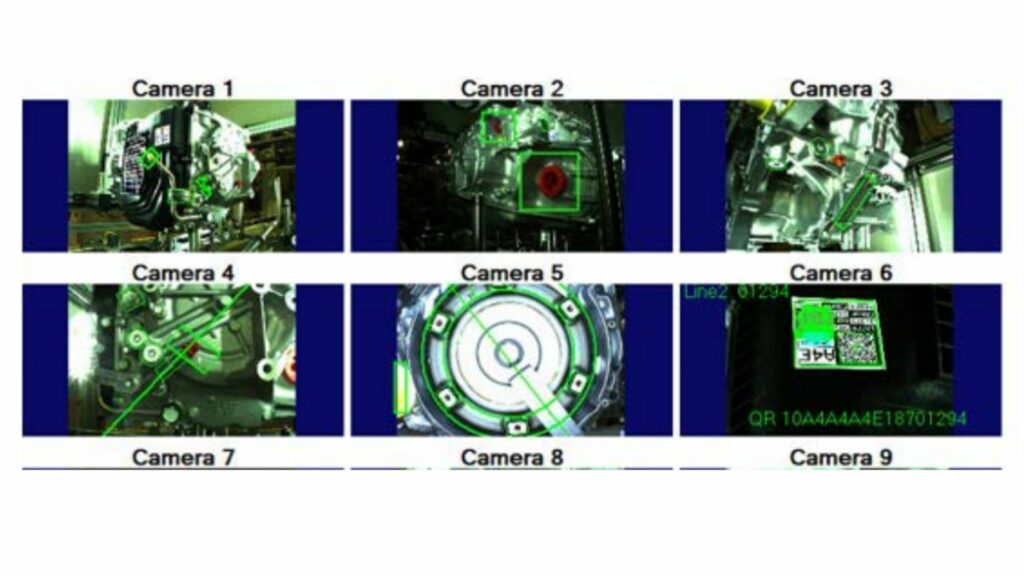

This Complex Surface Blemish Inspection system contains a nine-axis camera driven walking beam with flipping

Read more

The purpose of this Flashing, Debris, Surface Damage Inspection application is to identify damaged product

Read more

This inline tire inspection system in our vision lab demos top read and bottom read

Read more

Integro Technologies, a turnkey machine vision system integrator, recently worked with a customer who had

Read more

3D imaging is making a big impact in Logistics automation solving many applications that plague

Read more

The FDA has directed that all medical devices contain UDI by 2021. By adopting the

Read more

Bullseye Rapid Tube and Lumen Vision Inspection System is designed to measure the outer diameter

Read more

The OmniView Cylindrical 360-degree Product Inspection System acquires images from 4-5 cameras, and combines/stitches the

Read more

Integro Technologies specializes in machine vision inspection solutions for bottle inspection. Integro provides vision inspection

Read more

Integro Technologies has extensive experience in ID traceability inspection solutions. Manufacturers are turning to traceability

Read more

The glass jar inspection system evaluates a glass jar with a 360-degree view for small

Read more

Utilizing a combination of software, optical, and ultra-high resolution image formation technology, this is a

Read more

The patented Tire Inspection, known as the Tire Guardian Series, allows the automotive industry to

Read more

This high speed, bushing inspection system inspects 300ppm. This backlit, singulation, material handling, rejection tracking

Read more

540-degree inspection of filter mesh and injected molded assembly Function Inspection of plastic and mesh

Read more

This metal disk inspection system is an ideal vision system for 360 part inspection. This

Read more

Our customers are industry leaders in automotive, aerospace, pharma, medical, food, beverage, and consumer products.

Read more

3D Glue Bead Inspection is the Solution for Precise Adhesive Dispensing Adhesive dispensing is becoming

Read more

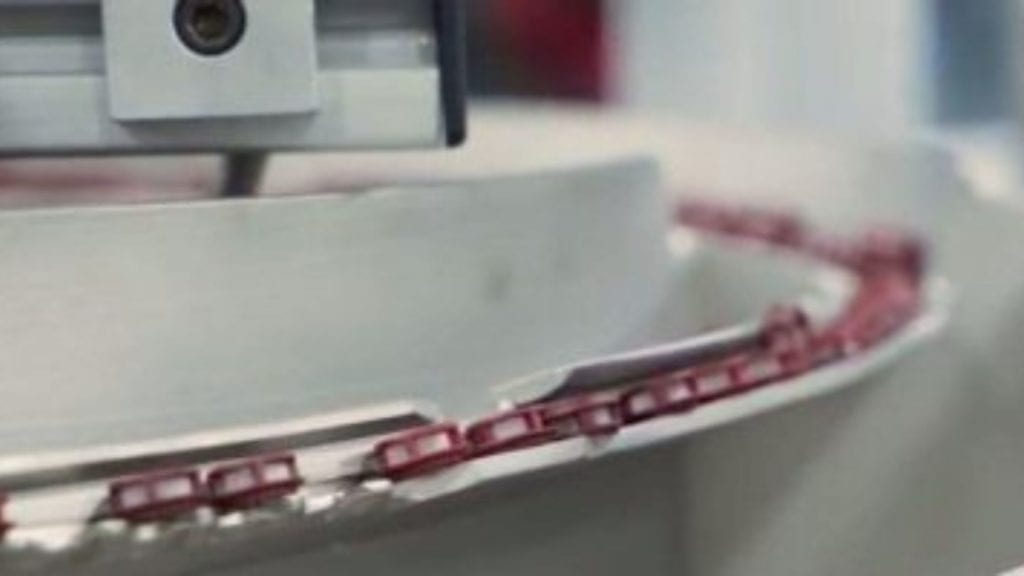

Singulation of Flats Bubble Sleeves and Letter Detection can be difficult to achieve in any

Read more

Singulation of Flat Envelopes and Bubble Sleeve inspection can be difficult to achieve in any

Read more

Integro Technologies has extensive experience in the application of deep learning for classification. For this

Read more

Integro provides 3D Bin Picking Pick N Place solutions for a wide variety of products

Read more

Integro Technologies has designed and developed an easy, one-stop, no contact solution to detecting a

Read more

Improve your product’s quality and safety with hyperspectral instruments. Define meat’s chemical quality: lean/fat content,

Read more

Reduce Labor Costs Associated with Manual Screening. Eliminate Risk Associated with Manual Inspection (6’ social

Read more

The material handling label inspection system represents a low volume 360-degree visualization and inspection solution

Read more

Cylindrical Bushing Internal Coating Verification and Dimensional Analysis System This high speed, (300ppm) backlit, singulation,

Read more

This manual 3D disk inspection and laser marking machine uses one camera to scan the

Read more

Machine Vision training is in demand than ever before, but finding sufficient time on the

Read more

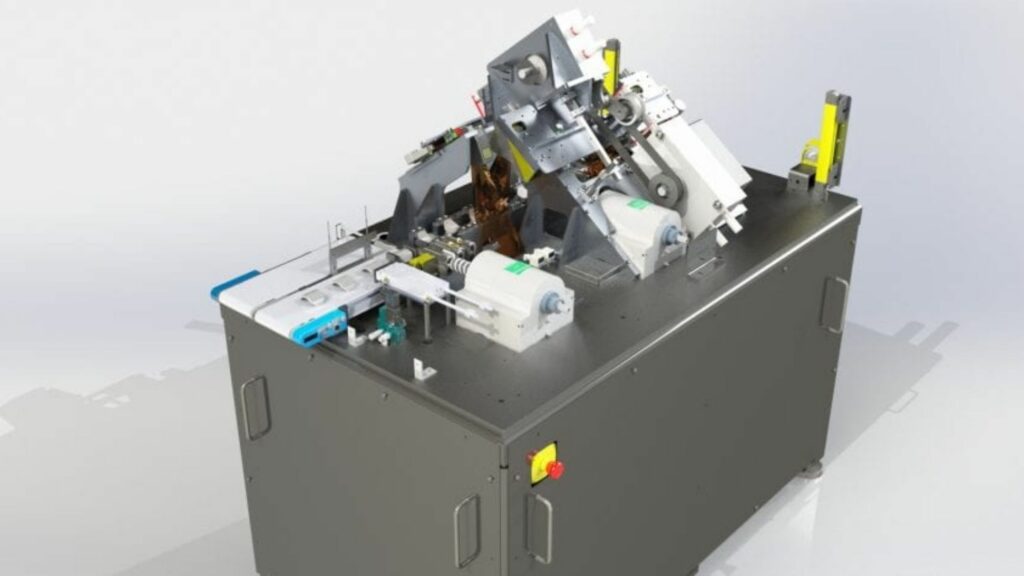

Reduce defects and production costs with Integro Technologies’ FastBuild Enclosure for Machine Vision and ID

Read more

Integro Technologies now offers packaging and label inspection solutions for the CBD industry. Machine vision

Read more

This video illustrates a color and 3D image capture and machine vision analysis of building

Read more

The Integro wood and composite 3D vision inspection system images and analyzes the entire perimeter

Read more

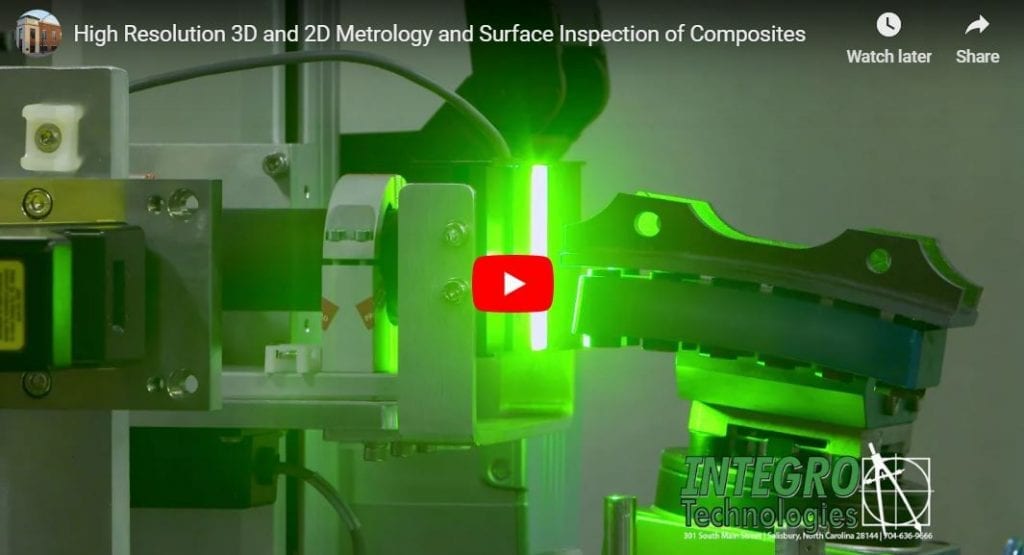

High-Resolution 3D and 2D Metrology and Surface Inspection of Composites This vision inspection system from

Read more

This 3D height measurement system by Integro Technologies is capable of imaging a variety of

Read more

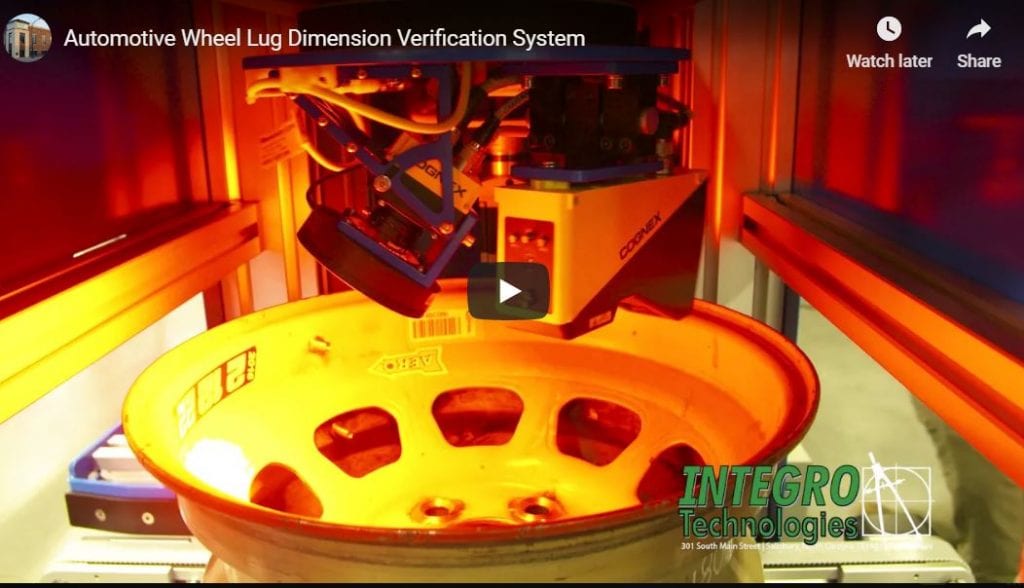

The Automotive Wheel Lug Dimensional Verification System by Integro Technologies uses 3D-Laser profiling technology to

Read more

This machine is inspecting two different small metal rocker part types at a rate of

Read more

The material handling system represents a low volume 360-degree visualization and inspection solution for consumer

Read more

When working with food, there's nothing more important than safety. One wrong move can poison

Read more

Integro is implementing a new high speed singulation system to improve visual canister inspection capability

Read more

Integro implements a print registration inspection system on pliable 100” textile web moving at 50fpm

Read more

Integro ships two new next generation multi-spectral visual inspection system to medical device manufacture in

Read more

The Integro high-speed tool bit inspection system processes one part every two seconds. Customer part

Read more

The wheel inspection system by Integro Technologies uses 3D-Laser profiling technology to evaluate key measures

Read more

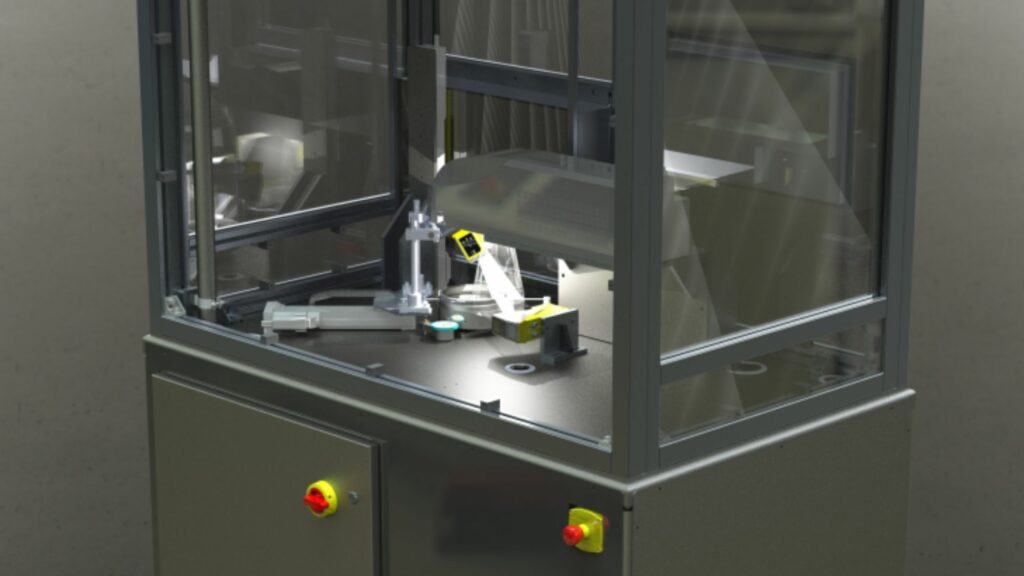

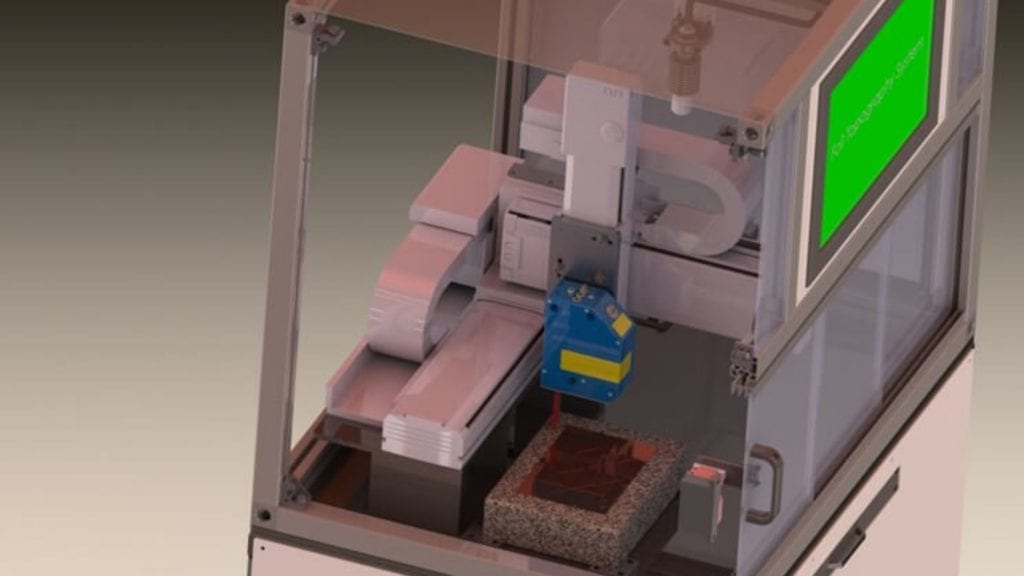

Integro is designing a tabletop medical laboratory visual inspection device to verify discrete components count,

Read more

Integro Technologies is a trusted source in machine vision technology for the food and beverage industries.

Read more

This plastic container vision inspection machine was developed to inspect 100% of the internal and

Read more

High Speed Vision Inspection for Manufacturers From electronic consumer devices to industrial automation controls and

Read more

Coherix Robust3D is a high-speed, in-line, error-proofing solution designed and built to provide 100% error-proof

Read more

This high speed syringe inspection system is a six (6) Cognex In-Sight camera solution inspecting

Read more

Integro Technologies partnered with Yamaha Robotics and the Coherix Predator 3D product to combine a

Read more

When your plastic parts lines are humming along at high-speed inspection rates of 30 fps

Read more

Function and purpose of this application is to remove Anodes/Cathode from cassette and place them

Read more

Function and purpose of this application: Carbon filter trays are delivered to the system and

Read more

The purpose of this application is to verify the correct three digits are present and

Read more

The purpose of this application was to inspect colostomy bags in web form within final

Read more

Function Inspection of plastic and mesh automotive filters to detect missing, broken, misshaped or flagging

Read more

Predator3D is the latest 3D machine vision technology from Coherix for structural adhesive and dispensing

Read more

Cognex ViDi Suite offers significant advantages in terms of performance and simplicity for configuring and

Read more

Inspect or verify pallets, case, or carton layering and/or kitting systems for medical, automotive, pharmaceutical

Read more

This application by Integro Technologies is a 360° inspection of ice cream containers. Data matrix

Read more

This round disk surface inspection is an ideal vision system for 360 part inspection. This

Read more

3D Vision Inspector Using a 2.2 micrometer-sensitive 3D laser mounted to a 3-axis robot, several

Read more

This customizable Copper Fitting Vision Inspection machine offers full verification of part geometry and validation

Read more

While many machine vision systems are two-dimensional, a growing trend towards 3D technology is making

Read more

Integro Technologies is a leader in machine vision inspection systems. Integro Technologies is an industry

Read more

Surgical tubing is extruded at rates on the order of 600 feet per minute. It’s

Read more

Vi